نشر مقالة علمية للتدريسي الاستاذ الدكتور عبد الله جبار حسين بعنوان Modern tribology and its special applications

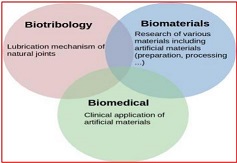

Modern tribology and its special applications<br />Ass.prof. Dr. Abdullah Jabar Hussain<br />Tribology is the science and technology of interacting surfaces in relative motion and of <br />related subjects and practices. The nature and consequences of the interactions that take <br />place at the moving interface control its friction, wear, and lubrication behavior. <br />Understanding the nature of these interactions and solving the technological problems <br />associated with the interfacial phenomena constitute the essence of tribology. The field of <br />tribology incorporates a number of disciplines, including mechanical engineering, <br />materials science, mechanics, surface chemistry, surface physics and a multitude of <br />subjects, such as surface characterization, friction, wear, lubrication, bearing materials, <br />lubricants, and the selection and design of lubrication systems, and it forms a vital <br />element of engineering.<br />The importance of friction and wear control cannot be overemphasized for economic <br />reasons and long-term reliability. It is important that all designers of mechanical systems <br />use appropriate means to reduce friction and wear, through the proper selection of <br />bearings and the selection of appropriate lubricants and materials for all interacting <br />surfaces. It is equally important that those involved with manufacturing understand the <br />tribological origins of unwanted friction, excessive wear, and lubrication failure in their <br />equipment. The lack of consideration of tribological fundamentals in design and <br />manufacturing is responsible for vast economic losses, including shortened life, excessive <br />equipment downtime, and large expenditures of energy.<br />The recent emergence and proliferation of proximal probes (in particular tip-based <br />microscopies and the surface force apparatus) and of computational techniques for <br />simulating tip-surface interactions and interfacial properties has allowed systematic <br />investigations of interfacial problems with high resolution as well as ways and means for <br />modifying and manipulating nanostructures.<br />These advances provide the impetus for research aimed at developing a fundamental <br />understanding of the nature and consequences of the interactions between materials on <br />the atomic scale, and they guide the rational design of material for technological <br />applications. In short, they have led to the appearance of the new field of micro/Nano <br />tribology.<br />There are also new applications which require detailed understanding of the tribological <br />processes on macro- and micro scales. Since the early 1980s, tribology of magnetic storage <br />systems has become one of the important parts of tribology.<br />Microelectromechanical Systems (MEMS) have begun to appear in the marketplace which <br />present new tribological challenges. Tribology of processing systems such as copiers, <br />printers, scanners, and cameras is important, although it has not received much attention. <br />Along with the new industrial applications, there has been development of new materials, <br />coatings, and treatments, such as synthetic diamond, true diamond, diamond-like carbon <br />films, and chemically grafted films, to name a few. It is clear that the general field of <br />tribology has grown rapidly during the past 50 years.<br />Conventional tribology is well established, but micro/Nano tribology is evolving and is <br />expected to take center stage for the next decade. New materials are needed, and their <br />development requires fundamental understanding of tribological processes. Furthermore, <br />new industrial applications continue to evolve with their unique challenges. Much of the <br />new tribological information has not made it into the hands.<br />The tribology deals with rough surface contact and accordingly numerical methods for <br />such surface are strongly needed to evaluate such situations as follows:-<br />An alternative numerical method for solving contact problems for real rough surfaces is <br />proposed in all tribological problems. The real area of contact and the contact pressure <br />distribution are determined using a single-loop iteration scheme based on the conjugate <br />gradient method, which converges for arbitrary rough surfaces. The surface deflections <br />and subsurface stresses are computed using an alternative two-dimensional multi-level <br />multi-summation algorithm, which allows the summation error to be kept under <br />the discretization error for any number of contact points.<br />The most interested area in tribology field is the biomedical tribology, however With <br />recent advancements in medical science, there have been improvements in the quality of <br />human life. The discoveries in the field of materials has positively impacted the <br />development of prosthetics and implants, which are becoming more biocompatible as well <br />as durable. To gain knowledge of the tribological characteristics of these materials, namely <br />friction, wear, and corrosion, is significant in order to further enhance their durability, <br />leading to a decrease in the frequency of surgical replacement and a more normal life for <br />the patient. Hence, this chapter explores the tribological implications of various materials <br />employed in biomedical applications which is include the followings:-<br /> Tribology of natural synovial joints and artificial replacements.<br /> Wear of dental implants.<br /> Wear and replacement of heart valves.<br /> Lubrication of pump in total artificial hearts.<br /> Ocular tribology and tribology of contact lenses.<br />The following figure illustrated apart of biomedical tribology material and elements<br />So, the biomaterials science and engineering has progressed quickly over the past decades, <br />the development of this field has shifted to the design of new materials and devices <br />wherein the functionality, reliability, and biocompatibility have become more specific and <br />significant. Tribology-related behavior is one of the key points for the above aspects. For <br />instance, The major clinical problem associated with artificial joints is excessive wear and <br />loosening, which can be attributed to their poor tribological properties and thus generated <br />wear debris. In addition, narrowing or blockage of artificial vascular due to surface <br />coagulation and damage to artificial heart valves owing to fatigue wear are also examples <br />of the failure of biomaterials and medical devices in tribology.<br />Therefore, to assure the functionality, reliability, and biocompatibility of biomaterials, <br />especially for long-term implanted medical devices, studying various tribological damage <br />mechanisms and obtaining optimum properties is one of the most important goals. Driven <br />by this point, more and more investigations have been conducted on fundamental <br />theories, bionic design, damage palliative related to tribology in biomedical applications. <br />Progress has been achieved, but problems remain to be answered. This is a challenging but <br />attractive task.<br />another advanced and interest area in tribology is the Nano tribology which is the <br />scientific study of friction and wear on the nanometer length scale, typically addressing <br />the sliding contact between a single asperity and a flat surface in well-controlled <br />conditions through experiments, modeling, and atomistic simulations.<br />The micro/Nano-tribological studies are needed to develop fundamental understanding of <br />interfacial phenomena on a small scale and to study interfacial phenomena involving <br />ultrathin films (as low as 1–2 nm) and in micro/nanostructures, both used in magnetic <br />storage systems, micro/nanoelectromechanical systems (MEMS/NEMS). <br />Also, Nano tribology is a branch of tribology that studies the phenomena of friction, wear, <br />adhesion and lubrication at the Nano scale, where atomic interactions and quantum <br />effects are important. This specialty aims to determine the properties of surfaces and <br />modify them for both scientific and technological purposes.<br />