The Impact of Insulating Materials on the Efficiency and Electrical artical by Asst. Lect. Ali Jaafar

The Influence of Dielectric Materials on Capacitor Efficiency and Electrical Performance

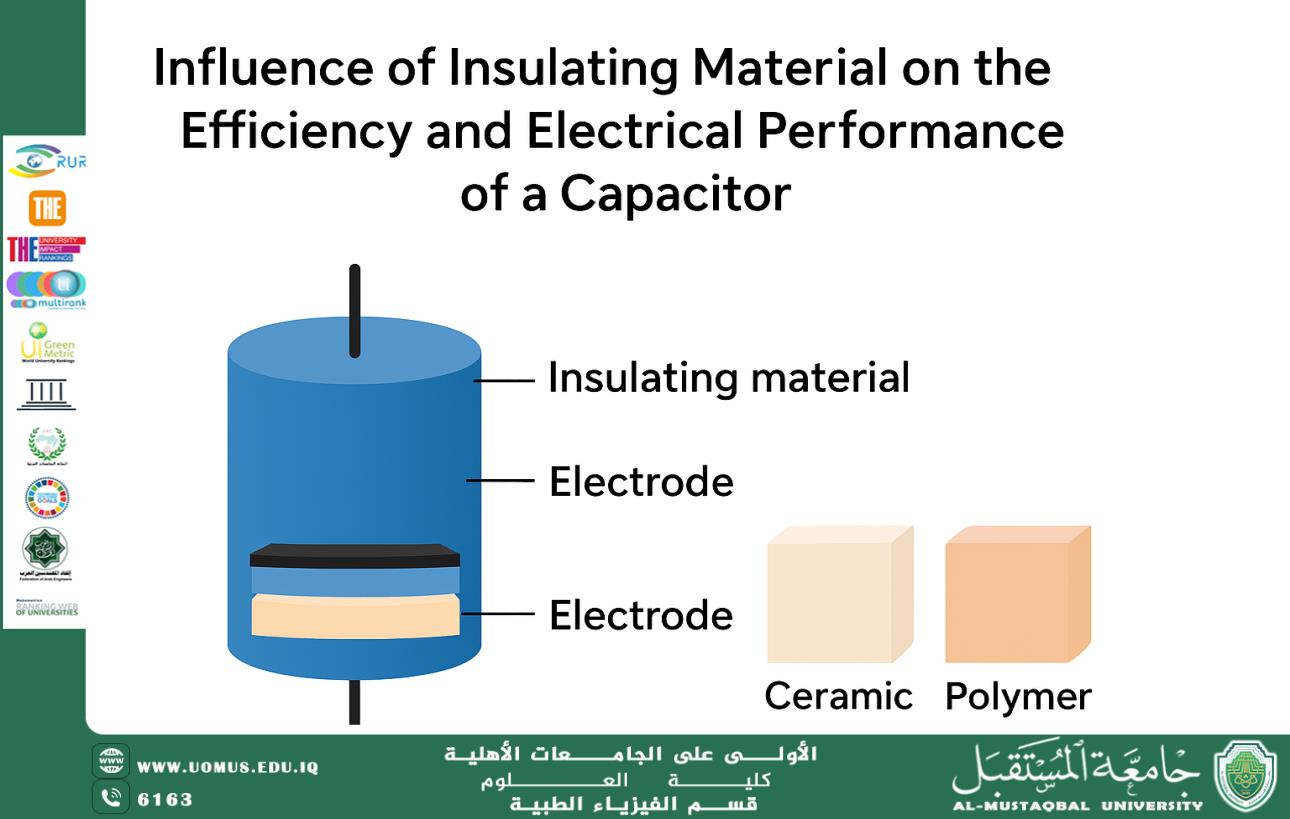

Dielectric materials play a pivotal role in determining the electrical characteristics of capacitors. A capacitor’s function does not rely solely on its conductive plates; its performance fundamentally depends on the nature of the dielectric medium separating these plates. The dielectric is the main component that determines the capacitor’s ability to store energy, its operational stability, and its response to electrical and environmental variations. Therefore, selecting an appropriate dielectric material is of great importance in designing capacitors and their scientific and industrial applications.

Dielectric materials differ in their structural composition and physical properties, leading to noticeable variations in the behavior of capacitors associated with them. The type of dielectric directly affects the amount of energy stored in the capacitor through its interaction with the electric field generated between the plates. The dielectric constant is one of the most important properties of a dielectric material, reflecting its ability to interact with the electric field by realigning its internal charges. The higher this constant, the greater the capacitor’s ability to store more charge, increasing its capacitance and allowing for a smaller size without compromising efficiency—an essential property for small electronic devices and precision systems.

In addition, the dielectric plays a critical role in limiting leakage currents. An ideal dielectric should have extremely high resistance to prevent charge flow; however, all dielectrics have some finite conductivity, which leads to small leakage currents. Higher leakage current indicates lower capacitor efficiency, as it causes energy loss and degrades performance over time. Therefore, materials with high resistance, such as ceramics and glass, are used in applications requiring high stability and minimal losses.

The thermal properties of the dielectric also affect capacitor performance under different operating conditions. Higher temperatures often change the arrangement of molecules within the material, which can affect the dielectric constant or the dielectric’s resistance to leakage. Some materials lose their properties when exposed to high temperatures, causing fluctuations in capacitance and reduced electrical stability. Thus, the thermal operating range of the dielectric must be considered according to the application’s requirements.

Another essential aspect is the dielectric’s ability to withstand high voltage. Each material has a maximum voltage it can tolerate before experiencing electrical breakdown, which causes it to lose its insulating properties. Breakdown poses a serious risk, potentially damaging the circuit or burning electronic components. Therefore, high-voltage capacitors, such as those used in power systems or high-voltage motors, utilize materials with high dielectric strength.

In addition to electrical and thermal properties, the dielectric’s frequency response is critically important, especially in communications and systems that rely on high-frequency signals. Some materials exhibit changes in behavior at high frequencies, affecting the capacitor’s efficiency in these applications. Consequently, specialized dielectrics have been developed to maintain stable properties across a wide frequency range.

Environmental factors, such as humidity, also affect dielectric materials. Water absorption can reduce dielectric resistance and increase leakage currents, weakening capacitor performance. Hence, moisture-resistant materials are used in harsh environments or applications requiring high reliability. Furthermore, structural defects or impurities in the dielectric can create weak points that accelerate electrical breakdown, necessitating strict quality standards in dielectric manufacturing.

With advances in materials science, it is now possible to use dielectrics with nanostructures or advanced composites that significantly improve performance. Nanomaterials have enhanced capacitance and reduced electrical losses by precisely controlling the dielectric’s internal structure. Modern manufacturing techniques, such as thin-film deposition and molecular chain modification, allow the development of dielectrics combining high thermal stability, increased capacitance, and low electrical losses, directly enhancing capacitor performance in advanced applications.

Overall, the dielectric material is not merely a separator between plates but represents the foundation of a capacitor’s electrical performance. It determines capacitance, stability, energy storage efficiency, and the capacitor’s ability to withstand various operating conditions. Therefore, designing modern capacitors requires careful study of dielectric properties to achieve a balance between electrical performance, thermal efficiency, and long-term stability, suitable for diverse industrial and scientific applications.

"AL_mustaqbal University is the first university in Iraq"