An article titled "Additive Manufacturing of Biodegradable Biomaterials for Sustainable Bone Repair" by Lecturer M.M. Abdullah Qais Hashim

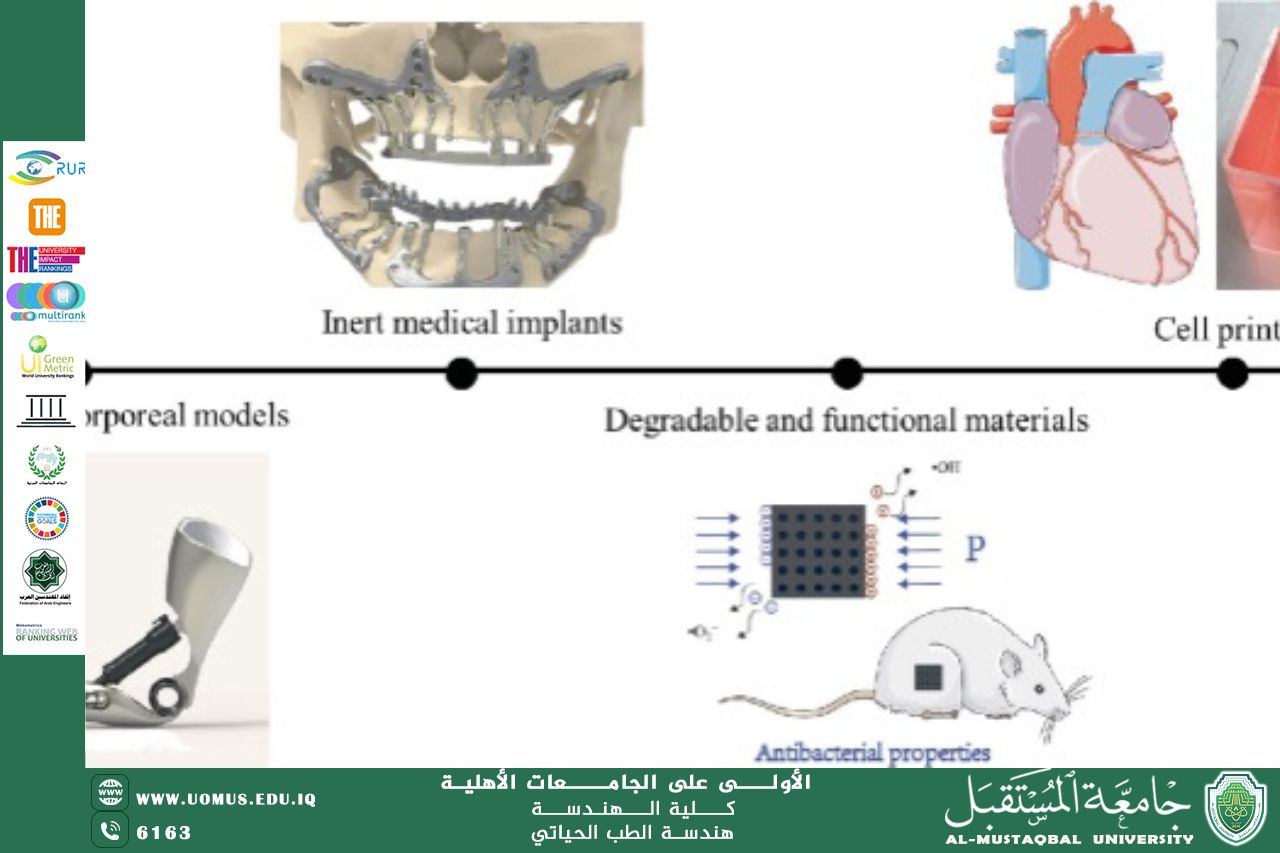

Additive Manufacturing (AM), widely known as three-dimensional (3D) printing, has become a key enabling technology in the design of sustainable biomaterials for bone repair applications. Unlike conventional manufacturing methods, AM allows layer-by-layer fabrication of complex structures with precise control over geometry, porosity, and material distribution. These characteristics are essential for developing biomaterials that closely mimic the natural structure of bone tissue.

In bone tissue engineering, biodegradable polymeric biomaterials such as polylactic acid (PLA) and polycaprolactone (PCL) are commonly used due to their biocompatibility and controlled degradation behavior. Using additive manufacturing, these materials can be fabricated into porous scaffolds that promote cell attachment, nutrient transport, and new bone formation. As the scaffold gradually degrades inside the body, it is replaced by natural tissue, eliminating the need for secondary surgical removal.

From a sustainability perspective, additive manufacturing offers significant advantages. Material waste is minimized because only the required amount of material is used during fabrication. In addition, patient-specific implants can be produced based on medical imaging data, reducing implant failure rates and improving long-term clinical outcomes. This personalized approach contributes to sustainable healthcare by lowering resource consumption and reducing medical waste.

Overall, the integration of additive manufacturing with biodegradable biomaterials represents a sustainable and efficient strategy for bone repair, supporting both advanced medical treatment and environmentally responsible design.