Four-Dimensional Bioprinting (4D Bioprinting): The Future of Living, Breathing Tissues

**Four-Dimensional Bioprinting (4D Bioprinting): The Future of Living, Breathing Tissues**

While the world is still trying to fully grasp the capabilities of three-dimensional printing, research laboratories in biomedical engineering have moved toward even more advanced horizons. This has led to the emergence of **four-dimensional bioprinting (4D Bioprinting)**. By adding **time** as a fourth dimension, printed tissues are transformed from static structures into intelligent systems capable of changing, growing, and responding to the biological environment inside the human body.

### What is Four-Dimensional Bioprinting?

This technology relies on the use of **smart materials** or stimulus-responsive polymers as **bio-ink**. The fundamental difference lies in the fact that the printed structure does not remain the same after leaving the printer; instead, it possesses **self-programming properties** that allow it to change its shape or function when exposed to external stimuli such as **temperature, humidity, pH changes, or the body’s electrical signals**.

### Why Is It a “Revolution” in Tissue Growth?

One of the biggest challenges of traditional 3D bioprinting in children is that the printed organ does not grow as the child grows, necessitating repeated surgical replacements. Here, 4D bioprinting offers a radical solution:

* **Adaptation to growth:** Designing heart valves or respiratory supports that automatically expand as the patient’s tissues grow.

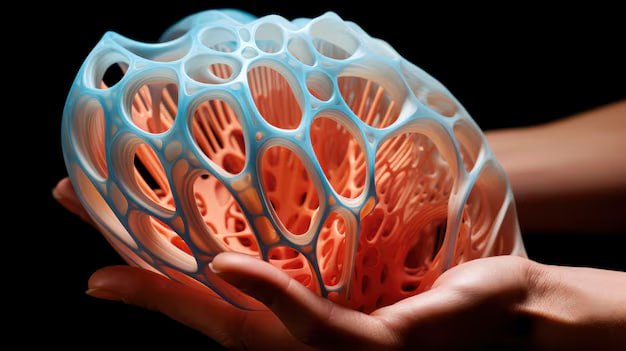

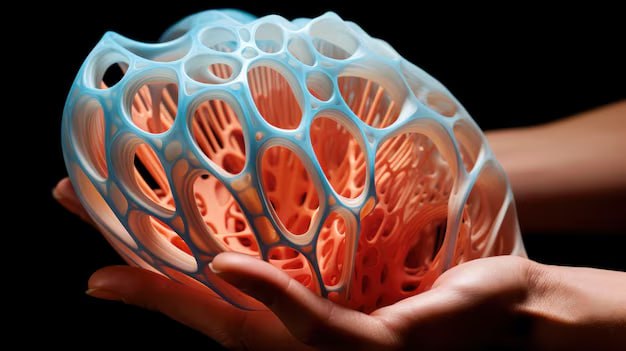

* **Self-folding:** The ability to print tissues in a flat form that later transform into complex structures (such as blood vessels) once implanted in the body.

* **Stimulation of cellular regeneration:** The materials used act as a nurturing environment that mimics the **extracellular matrix (ECM)**, encouraging stem cells to divide and differentiate naturally.

### The Future of the Profession and Its Applications in Prosthetics and Orthotics

For prosthetics and orthotics specialists, this technology opens the door to major advancements, including:

* **Smart orthoses:** Supports that adjust their flexibility and strength based on muscle pressure or limb temperature.

* **Bio-integrated interfaces:** Developing living, flexible connection points between the prosthetic limb and the body that prevent skin ulcers and adapt to changes in the volume of the residual limb.

### Conclusion

Four-dimensional bioprinting is not merely a technological luxury; it is the first step toward manufacturing human organs that **breathe and grow**. For biomedical engineering students, mastering these smart materials represents the real ticket to leadership in the medical job market of the coming decade.