Sustainability in the use of chitosan emulsion for the production of microspheres

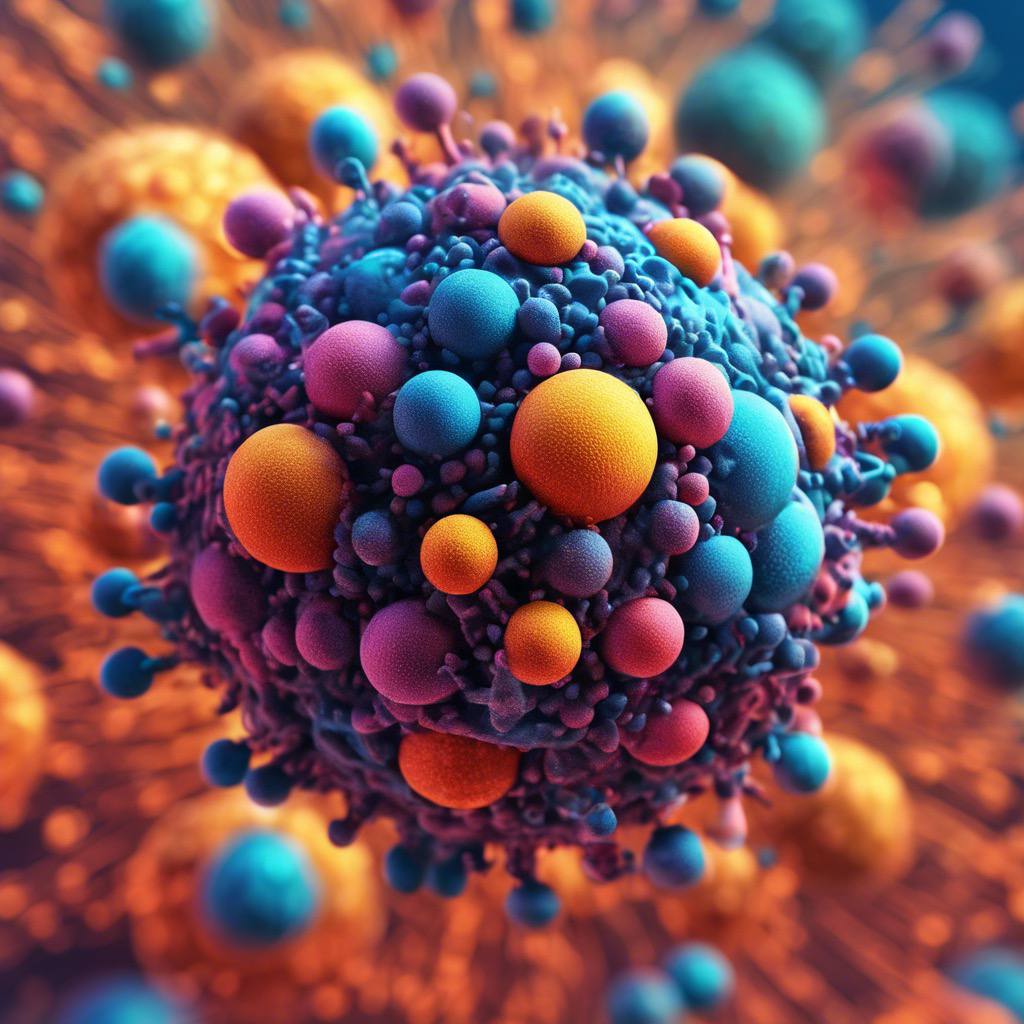

A scientific article by the engineer in the Department of Chemical Engineering and Petroleum Industries, Fatima Adi Ali Magdy, entitled (Sustainability in using chitosan emulsion to produce microspheres)<br />The content of the article is:<br />Sustainability in the use of chitosan emulsion for the production of microspheres<br /><br />Sustainability is one of the most important challenges facing the world today. As environmental and economic pressures increase, we must look for new ways to achieve sustainable development and preserve natural resources. One such innovative method is the use of chitosan emulsion to produce microspheres.<br /><br />Chitosan emulsion is a natural substance derived from the shell of shrimp and other crustaceans. It is distinguished by its excellent properties in improving the properties of microspheres and stabilizing them. Microspheres are considered one of the innovative technologies in the field of pharmaceutical manufacturing, as pharmaceutical compounds are encapsulated inside very small pellets to increase the effectiveness of the drug and improve its absorption.<br /><br />Utilizing chitosan emulsion in the production of microspheres is an important step towards sustainability. First, natural and renewable materials are used in the production of chitosan emulsion, reducing reliance on harmful chemicals. Secondly, the properties of the microspheres are improved and stabilized thanks to the unique properties of chitosan, resulting in increased effectiveness of the drug loaded in the pellets.<br /><br />In addition, chitosan emulsion has the property of biodegradation, which makes it easily degradable and reduces the impact<br />Chitosan emulsion has excellent environmental properties, as it is easily degraded by natural aquatic organisms, reducing negative impacts on the environment. In addition, the use of chitosan emulsion contributes to reducing waste generated during the microsphere production process, as the production process is optimized and losses are reduced.<br /><br />Drug-loaded microspheres are a versatile product in the pharmaceutical industry. They can be used to improve drug absorption, improve drug stability, and improve drug release at the target site in the body. By using chitosan emulsion in the production of microspheres, these benefits are achieved in a sustainable and environmental way.<br /><br />Moreover, chitosan emulsion can be used in other fields as well, such as food and agriculture industry. Shrimp shells and other crustaceans from which chitosan is extracted are surplus products in the fish industry, thus being utilized efficiently and reducing waste. Chitosan emulsion can be used in the food product industry as stabilizers and natural additives, and in the agricultural industry as biocides and plant growth enhancers.<br /><br />In summary, the use of chitosan emulsion in the production of microspheres is an important step towards sustainability, as it combines environmental benefits<br />How can chitosan emulsion contribute to reducing waste in the microsphere industry?<br />Chitosan emulsion can contribute to reducing waste in the microsphere industry in several ways:<br /><br />1. Production process improvement: Chitosan emulsion can be used to improve the microsphere formation process. It promotes mixture homogeneity and better distribution of drug compounds, reducing losses in the formulation process and thus reducing the amount of waste generated.<br /><br />2. Improving the stability of the microspheres: Chitosan emulsion contributes to improving the stability of the microspheres. It acts as a stabilizing agent that increases the bond strength between drug compounds and protects them from decomposition. This means that the pellets will be more stable and will not degrade as quickly, reducing waste resulting from drug degradation.<br /><br />3. Improving drug release: Chitosan emulsion can be used to improve drug release from microspheres. It has effective properties in improving the solubility of the drug and releasing it evenly and uniformly. This reduces wastage and increases the efficiency of drug use, which also reduces waste generated.<br />By using chitosan emulsion in the microsphere industry, a more efficient production process can be achieved and the amount of waste generated can be reduced. This contributes to achieving environmental sustainability and preserving natural resources.<br />3. What properties does chitosan emulsion have to improve microsphere manufacturing?<br />Chitosan emulsion possesses several properties that contribute to improving the manufacture of microspheres:<br /><br />1. Stabilizing properties: Chitosan emulsion acts as a stabilizing agent for drug compounds inside microspheres. It helps improve the cohesion strength between drug compounds, which maintains their stability and protects them from decomposition.<br /><br />2. Absorptive properties: Chitosan emulsion has excellent absorbent properties. It can effectively absorb liquids and drug compounds, which contributes to improving drug absorption when using microspheres.<br />3. Release properties: Chitosan emulsion has good release properties. When using microspheres loaded with chitosan emulsion, an even and uniform release of the drug is achieved. This helps in improving the efficiency of drug use and reducing wastage.<br /><br />4. Environmental properties: Chitosan emulsion is safe for the environment, as it is easily degraded by natural aquatic organisms. This reduces negative impacts on the environment and contributes to environmental sustainability.<br /><br />By using chitosan emulsion in the manufacture of microspheres, these properties can be utilized to improve the quality of the pellets and achieve better drug performance. The environmental properties of the emulsion can also be used to preserve the environment and reduce waste.