**Fire Extinguishing Methods in Chemical Plants**

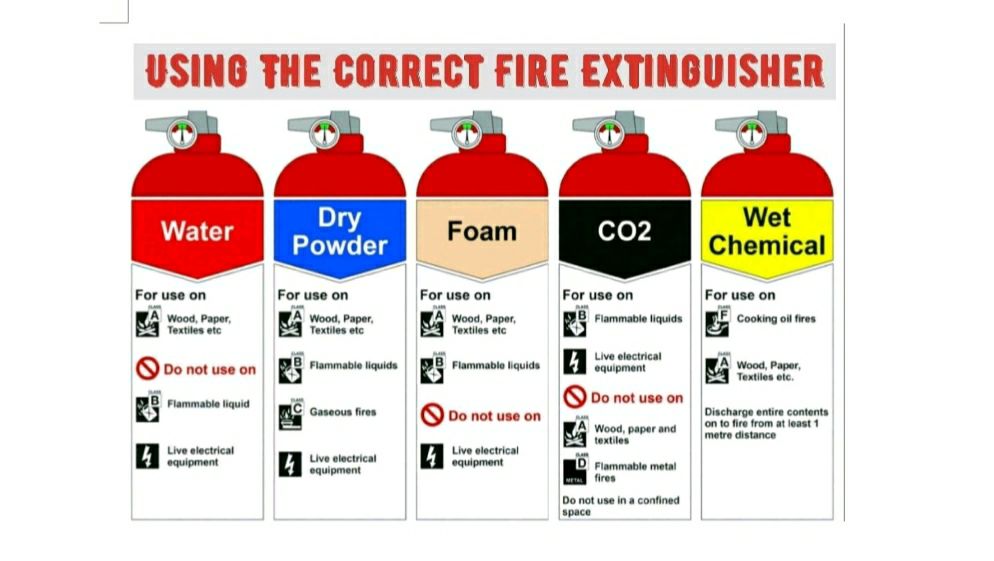

Malik Mustafa Mohammed, Head of the fuel and energy engineering techniques department<br />**Fire Extinguishing Methods in Chemical Plants**<br />Chemical plants represent high-risk environments due to the handling of flammable or explosive chemicals. Therefore, the design of fire extinguishing systems is an essential part of planning these facilities to ensure maximum safety. Below are the most commonly used fire extinguishing methods in chemical plants, along with practical examples:<br /><br />1. **Dry Chemical Fire Extinguishing System**<br /> Dry chemical fire extinguishing systems are commonly used in chemical plants due to their effectiveness in extinguishing various types of fires. For instance, in a plant manufacturing plastics based on petrochemicals, monoammonium phosphate can be used in dry extinguishing systems to combat fires caused by flammable liquids such as petroleum products and solvents. In chemical fertilizer plants, dry chemical systems are also integrated in areas near production units using chemicals like nitrates, as the ignition of nitrates can lead to dangerous explosions. The use of these systems ensures rapid fire control and prevents its spread to other sections of the plant.<br /><br />2. **High-Density Foam Fire Extinguishing System**<br /> High-density foam is widely used in chemical plants dealing with petroleum products. For example, in oil refining facilities, storage tanks are one of the most sensitive areas where foam systems are used to extinguish fires that may ignite in these tanks due to leaks or explosions. In dye manufacturing plants, where products contain flammable solvents, foam fire extinguishing systems are employed to cover production and storage areas. This ensures that any accidental ignition can be dealt with quickly and efficiently, preventing flames from spreading to other parts of the plant.<br /><br />3. **Carbon Dioxide (CO2) Fire Extinguishing System**<br /> Carbon dioxide is particularly used in enclosed areas or those containing electrical equipment. In precision electronics manufacturing plants, gas is used to clean components from impurities, and a small spark can ignite fires in the presence of sensitive chemicals. Here, the use of CO2 systems is ideal for preventing damage and maintaining equipment safety. Another example includes chemical plants producing industrial gases like hydrogen or oxygen, where the environment is saturated with flammable materials. CO2 systems are used to provide rapid extinguishing without causing collateral damage to equipment or reacting with sensitive chemicals.<br /><br />4. **Automatic Fire Extinguishing Systems Using Special Chemicals**<br /> Some chemical plants require the use of special chemicals to extinguish specific types of fires. For instance, in lightweight metal production plants such as magnesium, sodium chloride powder is used to extinguish fires caused by metal ignition. This type of fire cannot be extinguished with water or foam, as the reaction with water can exacerbate the fire's intensity. In battery manufacturing plants, where lithium and other chemical compounds are used, fire extinguishing systems with special chemicals are essential, as lithium ignition can lead to fires that cannot be extinguished by conventional means. Lithium carbonate powder is used effectively to extinguish such fires.<br /><br />5. **Halons and Environmentally Friendly Alternatives**<br /> Halons, particularly Bromo Chloro diFluoro Methane (1211) with the chemical formula CBrClF2, were widely used in chemical plants, especially in fire extinguishing systems for facilities with sensitive equipment or reactive chemicals. In pharmaceutical plants dealing with sensitive chemicals, halons were an ideal choice due to their ability to extinguish fires without leaving residues. However, with the gradual ban on halon use due to its harmful effects on the ozone layer, chemical plants have started adopting environmentally friendly alternatives such as FM-200 (heptaFluoro Propane, C₃HF₇) and Novec 1230, a fluoroketone compound consisting of carbon, fluorine, and oxygen (C6OF11). These materials are now used in electronic material manufacturing plants that require effective extinguishing without leaving residues that could disrupt production or contaminate products.<br /><br />6. **Integrated Plant Design and Fire Extinguishing Systems**<br /> Fire extinguishing systems must be an integral part of the plant's design from the outset. In petrochemical facilities, the fire extinguishing system should cover all critical areas, such as thermal cracking units, storage tanks, and loading/unloading areas. This can be achieved using a combination of foam and CO2 systems linked to an advanced fire alarm network. In fertilizer production plants, where raw materials like ammonia and nitrates are present, dry and wet chemical extinguishing systems should be precisely integrated to provide maximum protection. The design should also include safe and organized escape routes with regular training for workers to ensure their readiness for immediate response in emergencies.<br />**Conclusion**<br />Fire extinguishing in chemical plants requires a combination of advanced techniques and precise design to ensure the protection of lives and property. It is essential that extinguishing systems are effectively integrated into the plant's design to handle fires automatically without human intervention. The previous examples demonstrate that the choice of the appropriate method largely depends on the nature of the chemicals present in the plant.<br />Dhirar Salim Mohammed, a chemical engineer.<br /><br />