Introduction to the Electrospinning Process

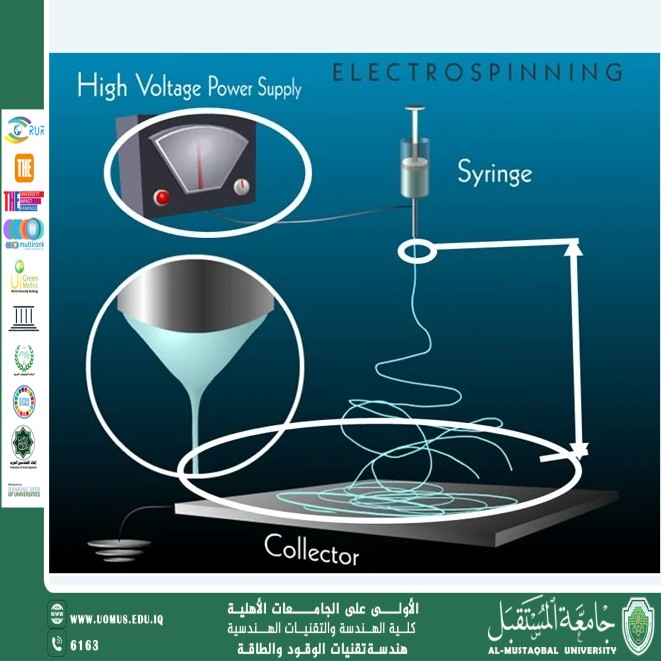

Introduction to the Electrospinning Process<br />Lecturer Maryam Ghassan Ghafar<br />SDG 3 – Good Health and Well-being<br />SDG 9 – Industry, Innovation, and Infrastructure<br />SDG 12 – Responsible Consumption and Production<br />SDG 6 – Clean Water and Sanitation<br />SDG 7 – Affordable and Clean Energy<br />Electrospinning finds use in several industries: life science, biotextiles, biomedical engineering, battery research, and the overall development, production, and commercialization of nanofiber materials. Diameters of the fibers typically range between tens of nanometers to a few micrometers. One of the main advantages of the electrospinning technique over other fabrication methods is its versatility to create fibers with multiple arrangements (ex. aligned fibers, random orientations, or their combinations) and morphological structures (ex. tubular scaffolds, flat surfaces, and asymmetrical configurations).<br />The popularity of the electrospinning technique has allowed multiple technologies — tissue engineering, regenerative medicine, and encapsulation of bioactive molecules — to emerge and significantly evolve over the past decade.<br />Nowadays electrospinning is not just exclusive to academic studies; it has received immense recognition and employment as a technique with real commercial applications. Multiple industries around the world have adopted this technique in the development of new product innovations.<br />Some applications that strongly benefit from and actively use electrospinning are tissue engineering (Phoenix Wound Matrix®, NanoAlignedTM, NanoECMTM, NanoCareTM, NanoMeshTM, Absorv®, TegadermTM), drug delivery (Rivelin® Patch), food encapsulation, insulating materials, energy conversion and storage, and air (Proveil) and water filtration, among others. These types of final samples usually go through current good manufacturing processes (cGMP), clearance through the food and drug administration (FDA), and/or follow guidelines like ISO-13485 for medical devices, and the F3510-21 from the ASTM international which is the Standard guide for characterizing fiber-based constructs for tissue-engineered medical products.<br />Al-Mustaqbal University The First University in Iraq<br /><br />