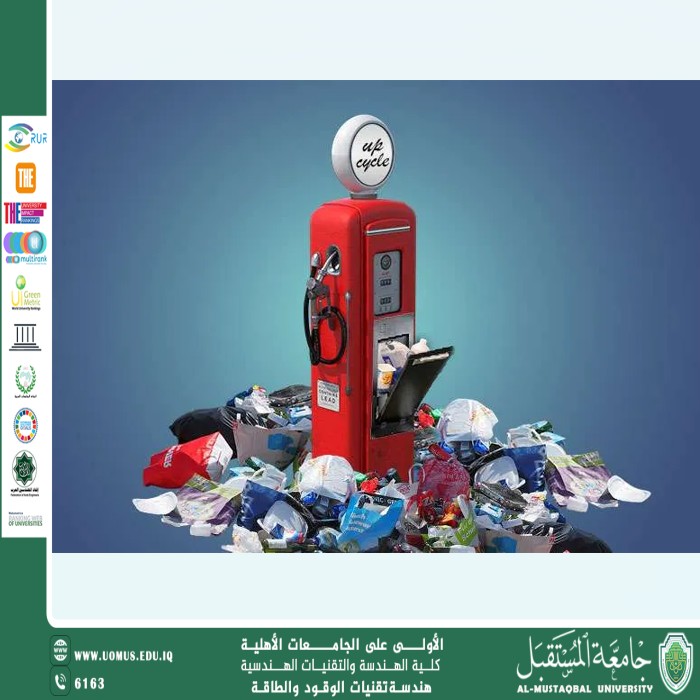

Converting nonrecyclable plastics into fuel

Converting nonrecyclable plastics into fuel<br />Dr. Malik Mustafa Mohammed<br />SDG 7 Affordable and clean energy<br />SDG 9 Industry, innovation and infrastructure<br />SDG 11 Sustainable cities and economies<br />Converting nonrecyclable plastics (e.g., mixed plastics, multi-layer packaging, contaminated plastics) into fuel is a promising waste-to-energy solution. This process typically involves thermal or catalytic conversion to break down long polymer chains into hydrocarbon fuels. Below is a structured overview of the key methods, steps, and considerations:<br />1. Feedstock Preparation<br />- Sorting: Separate nonrecyclable plastics from organic waste, metals, glass, etc.<br />- Shredding/Washing: Reduce plastic size (pellets or flakes) and remove contaminants (dirt, labels).<br />- Drying: Remove moisture to improve process efficiency.<br />2. Conversion Technologies<br />A. Pyrolysis<br />- Process: Thermal decomposition of plastics in the absence of oxygen at 300–500°C*.<br />- Steps:<br /> 1. Heating: Plastics are heated in a sealed reactor.<br /> 2. Vaporization: Long polymer chains break into smaller hydrocarbon vapors.<br /> 3Condensation: Vapors cool to form liquid hydrocarbons (pyrolysis oil).<br /> 4.Non-Condensable Gases: Light gases (methane, ethane, propane) are captured for energy use.<br />- Output:<br /> - Pyrolysis oil (40–80% yield): Can be refined into diesel, gasoline, or jet fuel.<br /> - Char/solid residue (5–15%): May contain catalysts or unreacted material.<br /> - Syngas (10–20%): Used to fuel the pyrolysis process.<br />- Best for: Polyethylene (PE), polypropylene (PP), polystyrene (PS).<br />B. Gasification<br />- Process Partial oxidation of plastics with limited oxygen/steam at 700–1,200°C to produce syngas (CO + H₂).<br />- Steps:<br /> 1. Gasification Reactor: Plastics react with oxygen/steam to form syngas.<br /> 2. Cleaning: Remove tar, particulates, and impurities.<br /> 3. Fischer-Tropsch Synthesis (optional): Convert syngas into liquid hydrocarbons.<br />- Output:<br /> - Syngas: Fuel for power generation or chemical synthesis.<br /> - Slag/residue: Inert material for construction applications.<br />- Best for: Mixed plastics (including PVC, PET).<br />C. Depolymerization<br />- Process: Chemical breakdown of polymers into monomers or smaller molecules using catalysts, solvents, or heat.<br />- Examples:<br /> - PET Depolymerization: Break into terephthalic acid and ethylene glycol.<br /> - Polyolefin Cracking: Use zeolite catalysts to convert PE/PP into diesel-range hydrocarbons.<br />- Output:<br /> - Monomers (for reuse in plastic production) or liquid fuels.<br />- Best for: Specific plastics like PET, polystyrene.<br /><br />D. Catalytic Cracking<br />- Process: Accelerate thermal decomposition using catalysts (e.g., zeolites, alumina) at lower temperatures (300–450°C).<br />- Advantages:<br /> - Higher selectivity for desired fuel fractions (e.g., gasoline, diesel).<br /> - Reduced energy consumption compared to thermal pyrolysis.<br />3. Post-Treatment of Fuels<br />- Distillation: Separate pyrolysis oil into fractions (light gases, gasoline, diesel, heavy oil).<br />- Hydroprocessing: Treat oil with hydrogen to remove sulfur, nitrogen, and impurities for cleaner fuels.<br />- Blending: Mix with conventional fuels to meet specifications.<br />4. Key Considerations<br />A. Challenges<br />- Feedstock Variability: Mixed plastics require pretreatment to avoid contamination.<br />- Energy Input: Pyrolysis/gasification are energy-intensive; self-sustaining systems use syngas for heat.<br />- Environmental Risks:<br /> - Emissions of dioxins/furans (especially from PVC).<br /> - Residual char may contain heavy metals.<br />- Economic Viability: High capital costs; profitability depends on feedstock supply and fuel prices.<br />B. Environmental Benefits<br />- Waste Reduction: Diverts plastics from landfills/incineration.<br />- Resource Recovery: Produces fuels that reduce reliance on fossil crude oil.<br />- Lower CO₂: Compared to landfilling, pyrolysis reduces methane emissions.<br /><br />5. Applications of Plastic-Derived Fuels<br />- ransportation Fuels: Diesel, gasoline, and aviation fuel substitutes.<br />- Industrial Fuel: Substitute for natural gas or heating oil.<br />- Chemical Feedstocks: Monomers for new plastic production (via depolymerization).<br />6. Commercial Examples<br />- Mura Technology (UK): Uses supercritical steam to depolymerize plastics into oil.<br />- Brightmark (USA): Operates pyrolysis plants converting plastics to diesel and wax.<br />- Agilyx (USA): Specializes in polystyrene-to-crude oil recycling.<br />Conclusion<br />Converting nonrecyclable plastics to fuel is technically feasible but requires careful management of =feedstock quality= , process efficiency, and environmental compliance=. Pyrolysis is the most widely adopted method, while catalytic and depolymerization approaches offer higher specificity. For large-scale implementation, integration with existing refining infrastructure and regulatory support are critical.<br /><br />Al-Mustaqbal University The First University in Iraq<br /><br />