How to produce white hydrogen

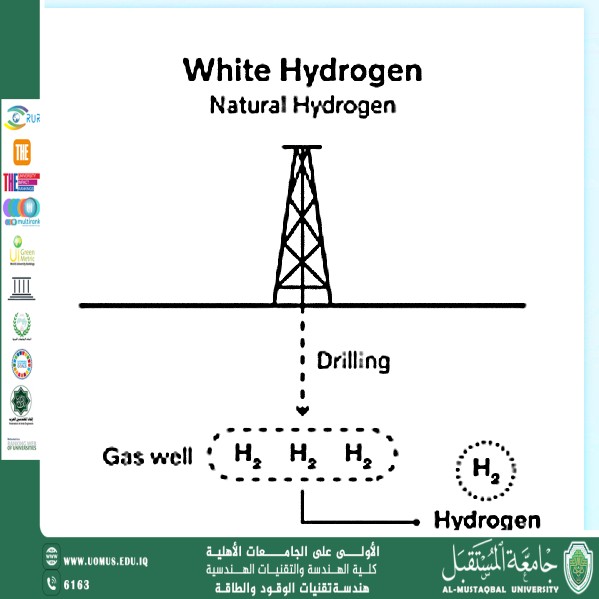

How to produce white hydrogen<br />Assist. Prof. Malik Mustafa Mohammed<br /><br />• SDG 7: Affordable and Clean Energy<br />• SDG9: Industry, Innovation and Infrastructure<br />• SDG 13: Climate Action<br />"White hydrogen" is not a formally recognized term in the energy industry, but it has been informally used to refer to naturally occurring hydrogen that is found in underground geological formations, similar to how natural gas or oil is extracted. Unlike other types of hydrogen (e.g., gray, blue, green), which are produced through industrial processes, white hydrogen is considered a naturally occurring resource.<br /> Process to Produce/Extract White Hydrogen:<br />The process for obtaining white hydrogen involves exploration and extraction from natural sources, much like fossil fuels. Here's an overview of the potential steps:1. Exploration & Discovery <br />- Geological Surveying : Use seismic imaging and geological data to identify areas where molecular hydrogen (H₂) may be trapped underground.<br />- Geochemical Analysis: Test soil, water, and rock samples for traces of natural hydrogen emissions.<br />- Natural Sources of Hydrogen:<br />- Ophiolites: Rocks formed in oceanic crust and upper mantle that can produce hydrogen through serpentinization (reaction of olivine with water).<br />- Radiogenic Reactions: Natural radioactive decay of elements like uranium and thorium in rocks can split water molecules into hydrogen.<br /> - Deep Earth Degassing: Hydrogen can escape from deep within the Earth’s mantle.<br /> 2. Drilling & Extraction <br />- Once a promising site is identified, exploratory drilling is conducted to confirm the presence of hydrogen gas.<br />- If viable, production wells are drilled to extract the hydrogen.<br />- The extracted gas may contain impurities such as methane, nitrogen, or CO₂, so gas separation technologies are used to purify the hydrogen.<br /> 3. Processing & Purification <br />- Gas Separation: Membranes, pressure swing adsorption (PSA), or cryogenic techniques may be used to isolate hydrogen from other gases.<br />- Compression or Liquefaction: Once purified, hydrogen is compressed or liquefied for transport and use.<br /> 4. Distribution & Use <br />- Transported via pipelines, trucks, or ships to end users for applications such as:<br /> - Fuel for fuel-cell vehicles<br /> - Industrial feedstock<br /> - Energy storage or power generation<br /> Advantages of White Hydrogen:<br />- Low Carbon Footprint: Since it’s naturally produced without fossil fuels or industrial processing, it can be very clean.<br />- Energy-Dense Resource: Could provide large amounts of usable hydrogen if significant deposits are found.<br />- No Electrolysis or Steam Reforming Needed: Avoids the high energy input required by green or gray hydrogen production.<br /> Challenges:<br />- Limited Known Reserves: Very few commercially viable natural hydrogen deposits have been identified so far.<br />- Exploration Costs: Finding and confirming deposits is expensive and technologically challenging.<br />- Infrastructure Gaps: Existing infrastructure is geared toward manufactured hydrogen, not natural extraction.<br />Current Status:<br />As of now, white hydrogen remains a niche concept. Most hydrogen currently used industrially is gray or brown hydrogen. However, interest in white hydrogen is growing due to its potential for being a sustainable and low-cost source of H₂ if substantial natural reserves can be discovered and exploited economically.<br /><br />"Al-Mustaqbal University – The No. 1 Private University in Iraq"<br />