The Most Important Methods of Optical Component Bonding

A Scientific Article by the Head of the Optics Technologies Department, Asst. Prof. Dr. Munther Sameen Shakir: The process of bonding optical parts or components using pressure bonding is one of the most important and precise techniques employed in attaching optical elements used in optical devices, whether they consist of glass or plastic lenses, such as bifocal lenses.

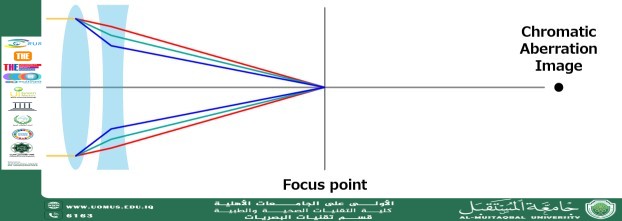

Most types of medical lenses used in various optical devices contain optical aberrations. It is preferable to reduce or eliminate these aberrations, including spherical and chromatic aberrations. Bonding is achieved by joining two or more lenses, provided that they are made from different materials.

Therefore, it is necessary to meet certain requirements during the process to obtain lenses free from defects:

Work must be conducted in a cleanroom free of dust particles, with a high level of cleanliness reaching

Cleanliness = 3 pcs per cm²,

and with the number of Newton’s rings between the spherical surfaces during bonding being N = 0.5.

The temperature inside the cleanroom (cleaning cabinet) should be 22–24°C.

The lenses must be inspected using precise technical instruments such as an

Interferometer or Collimator.

The external surfaces should be coated to increase transmittance and reduce the effect of ultraviolet radiation on the eye.

The bonded lenses cannot be separated for any reason except by using very high temperatures.