An article "Ultra High Performance Concrete (UHPC) and Its Role in Advancing Modern Construction Technologies" Dr. Asrar Samandar

Introduction

Ultra High Performance Concrete (UHPC) is one of the most advanced construction materials that has revolutionized modern building technology. It is characterized by exceptional strength, high density, and outstanding resistance to environmental and mechanical stresses, making it an ideal choice for advanced infrastructure projects and structures requiring performance beyond conventional concrete.

Definition of UHPC

UHPC is a high-density concrete based on ultra-fine materials and optimized mix designs. It exhibits compressive strength exceeding 150 MPa, along with excellent tensile and flexural strength. The addition of steel fibers enhances durability, while very low permeability and extended service life are among its most significant features.

Main Components of UHPC

UHPC consists of modified Portland cement, fine fillers such as silica fume and finely ground quartz, very fine aggregates typically without coarse aggregates, short steel fibers to improve flexural strength and crack resistance, advanced chemical admixtures such as superplasticizers, and a very low water content to achieve maximum density.

Key Properties of UHPC

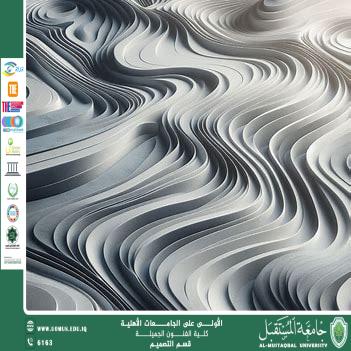

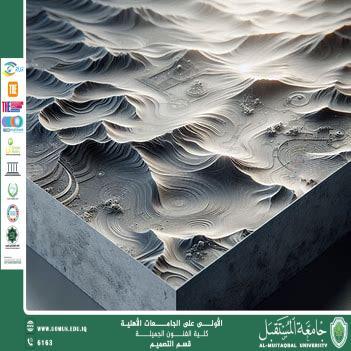

Its key properties include extremely high compressive strength ranging from 150 to 200 MPa, exceptional durability against salts and chemical agents, very low permeability preventing water and pollutant penetration, high ductility due to steel fiber reinforcement, a long service life that may exceed 100 years, and a smooth surface suitable for architectural and structural applications.

Advantages of Using UHPC in Construction Projects

UHPC allows for reduced structural element thickness without compromising strength, extends service life while reducing maintenance costs, enables slender and lightweight designs, enhances resistance to seismic and dynamic loads, and increases overall safety due to high resistance to cracking and corrosion.

Major Applications of UHPC

UHPC is widely used in bridges and walkways with long spans, high-rise buildings and architectural façade elements, marine structures and desalination plants, tunnels and blast-resistant structures, as well as industrial floors and precast concrete elements.

Challenges and Limitations

Despite its advantages, UHPC faces several challenges, including high cost compared to conventional concrete, the need for specialized expertise in mixing and casting, and sensitivity to low water content that requires precise control during production.

Conclusion

Ultra High Performance Concrete (UHPC) represents the future of the construction industry by combining exceptional strength with long-term durability and opening new horizons in structural and architectural design. Although challenges remain, continuous advancements in material technology make UHPC a strategic choice for projects requiring superior performance and long-term stability.

Almustaqbal University, The First University in Iraq.